The Future of Liquid Load Bank Testing

Delivering comprehensive test solutions for mission-critical data centers in the AI era.

“This partnership is built on exceptional engineering and a profound belief in each other’s respective areas of expertise,” said Sullivan. “Data center operators are assured of a comprehensive cooling and testing solution manufactured to the highest standards, helping them expand their capabilities for the AI era.”

Applications

Purpose-built for comprehensive commissioning, the LLB 670 ensures full validation of UPS systems, Technology Cooling Systems (TCS), and Technology Water Distribution Systems (TWDS). By simulating real-world load conditions, it verifies system performance, resilience, and reliability before going live.

OCP Wetted Materials Compliance

Fully compliant with Open Compute Project (OCP) guidelines for water based transfer fluids in single phase, cold plate-based liquid cooled racks, the LLB 670 is constructed with 316 Stainless Steel and INCOLOY 800 components to mitigate the risk of chloride crevice corrosion, ensuring long-term durability in demanding environments.

Safety Features

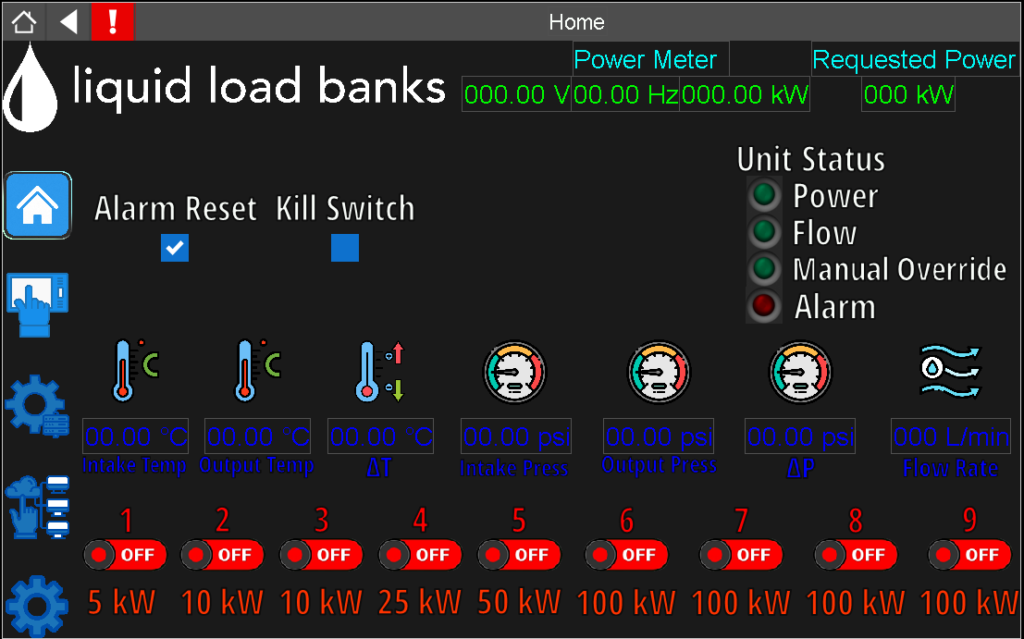

Engineered with multiple automatic protections, the LLB 670 features automatic shutdown mechanisms for minimum flow per kW, maximum temperature, and maximum pressure. These safeguards ensure the safe operation of both the load bank and the infrastructure under test, preventing potential failures during commissioning.

Instrumentation & Data Monitoring

The LLB 670 is equipped with advanced instrumentation, providing precise mechanical and electrical measurements that enable data centers to validate performance against their Service Level Agreements (SLAs). Mechanical parameters include input and output fluid temperature, input and output fluid pressure, and fluid flow rate, while electrical monitoring captures power (kW), current (Amps), and frequency (Hz). This high-fidelity data ensures accurate system testing, helping facilities meet operational and reliability commitments.